Pipe Clamp

Scope

Light series pipe clamps have application in 6 series size of general mechanicalpressure pipes which external diameters are from 6mm to 7.5mm.

Duplex series pipe clamps have application in 5 series size of general mechanical pressurepipes with external diameters are from 6mm to 42mm.

Heavy series pipe clamps have application in 8 series size of general mechanicalpressure pipes with external diameters are from 8mm to 220mm.

Material Properties

Property | Polypropylene | Nylon |

Density | 0.906g/cm3 | 1.12~1.15g/cm3 |

Bending Strength | 36N/mm2 | 130~200N/mm2 |

Impact Toughness | No break | No break |

Compressive Strength | 90N/mm2 | 120N/mm2 |

Modulus of Elasticity | 1500N/mm2 | 3000N/mm2 |

Tensile Strength | 25~35N/mm2 | 80~90N/mm2 |

Temperature Endurance | -30℃~+90℃ | -40℃~+120℃ |

Colour | Green, Blue. | Black |

Recommended distance of pipe clamp installation

Outer Diameter of Pipe | Distance of pipe clamp on pipe(mm) |

6~14 | 0.9 |

15~22 | 1.2 |

23~28 | 1.5 |

30~38 | 2 |

40~48.3 | 2.5 |

50~57 | 3 |

60.3~70 | 3.4 |

73~88.9 | 3.7 |

90~108 | 4 |

114~165.1 | 4.3 |

140~165.1 | 5 |

168.3~220 | 5.5 |

Assembly Instructions

Assembly on welding board

Before assembly, in order to fix the direction of pipe clamps, we suggest marking thisfix position where pipe clamps will be welded on, firstly put bottom half ofpipe clamp, and then place fixed pipe on it. Finally put on upper half of pipeclamp and fasten it by screw.

Note:Avoid to weld on board of installed pipe clamp directly.

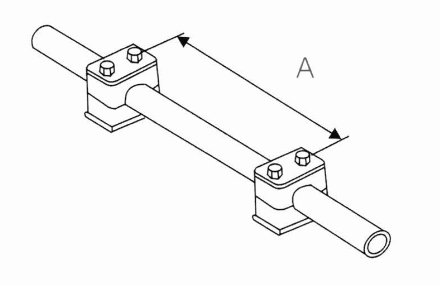

Install on the rails

Rails can be welded on the base, or be fixed with screw, and then push the rail nutsinto groove of the rails and then turn 90 degree, let the bottom half of pipeclamp into the nuts, put on the pipes to be fixed, then put the upper half ofthe pipe clamp and fasten it by screw.

Stackingassembly

Rails can be welded on the base, or be fixed with screw, and then install the bottomhalf of pipe clamp, put on the pipes to be fixed, finally put the upper half ofthe pipe clamp and fasten it by screw. It is the same for installing anotherpipe clamp.

Light series according to the first part of DIN3015 | |||||

Size of Series | Bolt for fixing | Polypropylene | Nylon | ||

Bolt fastening torque(N*M) | Pipe Clamp Force (KN) | Bolt fastening torque(N*M) | Pipe Clamp Force (KN) | ||

0 | M6 | 8 | 0.6 | 10 | 0.6 |

1 | M6 | 8 | 1.1 | 10 | 0.7 |

2 | M6 | 8 | 1.3 | 10 | 0.8 |

3 | M6 | 8 | 1.4 | 10 | 1.6 |

4 | M6 | 8 | 1.5 | 10 | 1.7 |

5 | M6 | 8 | 1.9 | 10 | 2.0 |

6 | M6 | 8 | 2.0 | 10 | 2.5 |

Heavy series according to the first part of DIN3015 | |||||

Size of Series | Bolt for fixing | Polypropylene | Nylon | ||

Bolt fastening torque(N*M) | Pipe Clamp Force (KN) | Bolt fastening torque(N*M) | Pipe Clamp Force (KN) | ||

1 | M10 | 12 | 1.6 | 20 | 4.2 |

2 | M10 | 12 | 2.9 | 20 | 4.5 |

3 | M10 | 15 | 3.3 | 25 | 5.1 |

4 | M12 | 30 | 8.2 | 40 | 9.3 |

5 | M16 | 45 | 11.0 | 55 | 21.0 |

6 | M20 | 80 | 14.0 | 150 | 25.8 |

7 | M24 | 110 | 28.0 | 300 | 32.0 |

8 | M30 | 180 | 40.0 | 350 | 48.0 |

Duplex series according to the first part of DIN3015 | |||||

Size of Series | Bolt for fixing | Polypropylene | Nylon | ||

Bolt fastening torque(N*M) | Pipe Clamp Force (KN) | Bolt fastening torque(N*M) | Pipe Clamp Force (KN) | ||

1 | M6 | 5 | 0.9 | 5 | 0.9 |

2 | M6 | 12 | 2.1 | 12 | 2.2 |

3 | M8 | 12 | 1.9 | 12 | 2.0 |

4 | M8 | 12 | 2.7 | 12 | 2.9 |

5 | M8 | 8 | 1.7 | 8 | 2.5 |

|